The right way to cut with a scroll saw: Make your sawing projects a success!

Filigree woodworking for model making, for example, is probably one of the core disciplines of woodworking. Artful cut-outs, decorative edges or letters made of wood – it is rare for these tasks to be carried out with a conventional fretwork saw in a DIYer's workshop. However, this work can be really precise with the electric version of the fretwork saw – the scroll saw.

The stationary saw is compact and finds a place in even the smallest workshops. However – even more so than with other saws – practice really does make perfect! The workpiece is guided through the clamped saw blade using both hands, which may not always be simple. But once you have got a feel for how to properly handle the scroll saw, you'll no longer want to do without it. We will give you tips on what you need to pay attention to, to make your projects a success with the Einhell scroll saw.

How does a scroll saw work?

The scroll saw is essentially an electric fretwork saw. The clamped saw blade is automatically moved up and down quickly in a stroke movement, depending on the set speed. This means that, unlike when working with the fretwork saw, you have both hands free to guide your workpiece precisely through the saw blade. Care should be taken to apply the workpiece to the saw blade only with a small amount of pressure and then to advance it carefully with both hands.

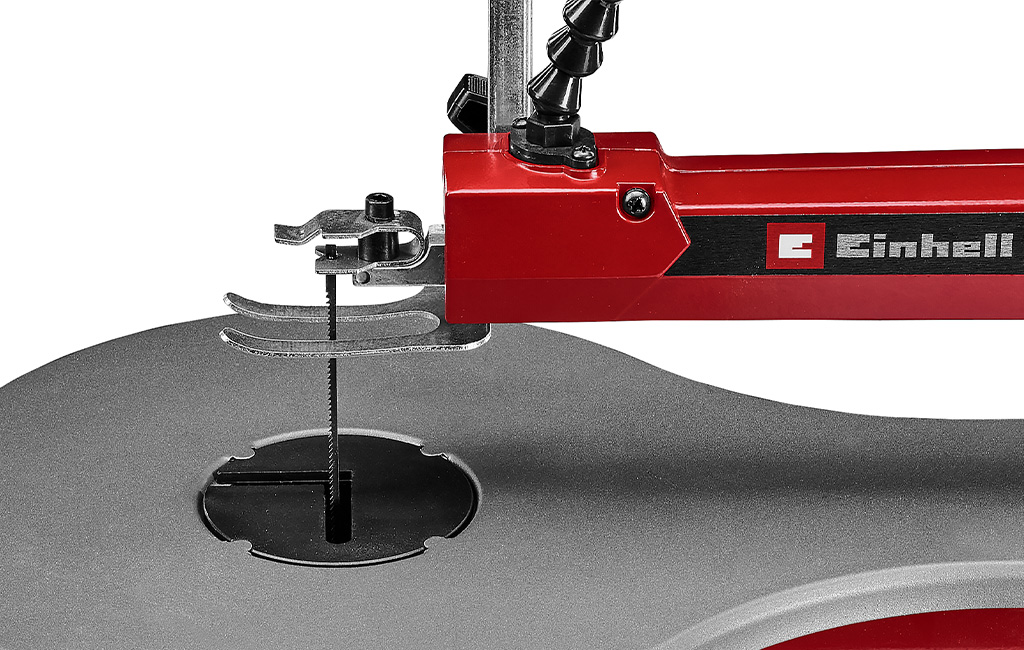

Workpiece hold-down

The Einhell scroll saw TC-SS 406 E is equipped with some useful functions to ensure that even fine work can be completed cleanly and as easily as possible. The integrated workpiece hold-down, for example, ensures that the wood you are working on is held down while working with the saw. This makes it easier for you to guide your workpiece cleanly.

Tiltable workbench

Have a lot of different projects planned and need a scroll saw that you can adjust individually? Our saw is even equipped with a workbench that can be tilted without tools! This allows you to optimally perform oblique or mitre cuts. The stable workbench can be adjusted up to an angle of 45°.

Blowing device & suction adapter

In addition, you should always have a clear view of your working area. For this purpose, our saw has both a blowing device, which blows the sawdust from the work table, and a suction adapter, to which you can connect a wet-dry vacuum cleaner, for example, in order to suck the chips up straight away.

The right saw blades for each task

You should choose a suitable saw blade appropriate for the material you are working on and the shapes you want to saw. The saw blades already differ in how they can be clamped in the scroll saw, and there are saw blades with and without a pin. Scroll saw blades with cross-pin are simply clamped by fixing the pin by the scroll saw bow. The Einhell scroll saw is equipped with a quick-release clamp, which quickly and easily clamps and fixes both pin saw blades and saw blades without a pin, and can also be used to change the blades.

The saw blades for scroll saws also differ in their thickness and cutting thickness. The thinner the blade, the finer cuts and contours you will be able to saw. However, fine blades are also less stable and more prone to break. Therefore, you should always select the thickness of the saw blade to match the material. The saw blades also differ in the toothing. Depending on the manufacturer, you have a wide selection of saw blades. The following three types of saw blades will certainly be encountered more often:

- Round blades: Particularly suitable for sawing round shapes, narrow radii, details and fine contours

- Straight blades: Saw quickly and precisely, especially longer, straight lines and corners, but less suitable for detailed work

- Counter-tooth saw blades: Saw very fine and clean lines because the upward and downward directed saw teeth prevent tears in the wood when the saw blade moves upwards

Tips for particularly fine and precise cuts

1. Check the saw blade and clamp it properly

The most important thing, as with all hand-held and stationary saws, is that the saw blade is in perfect condition. Clean cuts are only possible if the saw blade is sharp and intact, i.e. if it has no cracks, broken saw teeth or other changes in shape. In addition, the saw blade should always be properly clamped. The saw teeth must always point downwards in the direction of the workpiece. With the scroll saw TC-SS 406 E, you can clamp the saw blade without tools thanks to the quick-clamping device. You can check that it is properly clamped with a simple test: The saw blade should yield slightly when you press against it with one finger, but not more than 3 mm. The more you work with the electric fretwork saw, the faster you will develop a sense of how best to clamp the various saw blades.

2. Draw or use a template

Know what your work should look like and you already have practice with the scroll saw? Then, of course, you can try to saw freely! However, if you are not yet an expert in handling the tool, it is best to draw the desired result on the workpiece or to use a template. The easiest way to do this is to draw directly on the wood with a dark pencil and then saw exactly along this line. If there are any pencil marks visible at the end, you can saw a little bit more or simply sand the residue with some sandpaper.

3. Preparing the workpiece: Pre-sawing or pre-drilling

Smaller workpieces can be guided through the saw more easily and precisely. So, if your piece of wood is quite large and your template is smaller, you can make your work easier by sawing the large workpiece in advance. Want to make cut-out sections in that piece of wood? Then you'll need to pre-drill first. In the line you want to saw off, or in a free area next to the line that will fall out later, you need to drill a hole that is at least as large as the thickness of your saw blade. Then you can guide your saw blade through the pre-drilled hole, clamp it with the help of the quick-clamping device and get started.

4. How do you avoid ugly rips?

First of all, you should remember that the result always depends significantly on the saw blade used! The saw blade should be selected to suit the material and thickness of the workpiece. If you are working with a material for the first time, you can first try sawing with just a few strokes. Then gradually increase this until you feel that you can guide your workpiece precisely and safely through the saw. If your saw blade still breaks out or there are unsightly cracks in the wood, you should guide the workpiece more carefully and slowly and check that the workpiece holder holds down the wood as securely as possible. A very fine saw blade with a high number of teeth can also help to avoid cracks. The fine saw blade saws slower but cleaner.

Summary: Practice really does make perfect!

As you can see, even small details can have an impact on the final result. Have you chosen the right saw blade, is your stroke speed adapted to the material and are you guiding the workpiece correctly through the saw? Ultimately, here too, as so often in life: practice really does make perfect! The more smaller and larger handcraft projects you complete with your scroll saw, the more confident you will be in choosing your material, the right saw blade and how to use it.

Our tip: Start with smaller "practice projects"; for example, saw individual letters made of wood of different thicknesses and use different types of wood. This will help you gain experience with the scroll saw so you can soon tackle difficult projects – after all, you won't become an expert overnight.