Band saw applications

As well as drilling and screwing, sawing is one of the most common tasks in a DIYer's workshop.There are various different types of saws for different uses. The classic choice, apart from the simple hand saw, is clearly the jig saw, which can be found in most households. This is closely followed by the circular saw or even the table saw. However, few home workshops have a band saw. Although the band saw is one of the most interesting saws for use around the house, it is usually one of the last tools a typical DIYer gets.

Band saw applications are more diverse than they might seem at first glance.

In this article I will try to give you an overview of a few use cases of the band saw.

Simple cutting of strips and boards

A strip, be it a skirting board or a roof batten, rarely has the desired length when you purchase it. The band saw can start cutting immediately after measuring and marking. The fact that you hold the workpiece on the band saw with both hands, eliminates time-consuming bracing of the workpiece in the vice or tedious attachment of clamps, as is necessary, for example, when working with a jig saw or a hand saw. Compared to the table saw, the preparation time is practically non-existent. If you've had a little practice, even the smallest workpieces can be processed.

The band saw and different materials

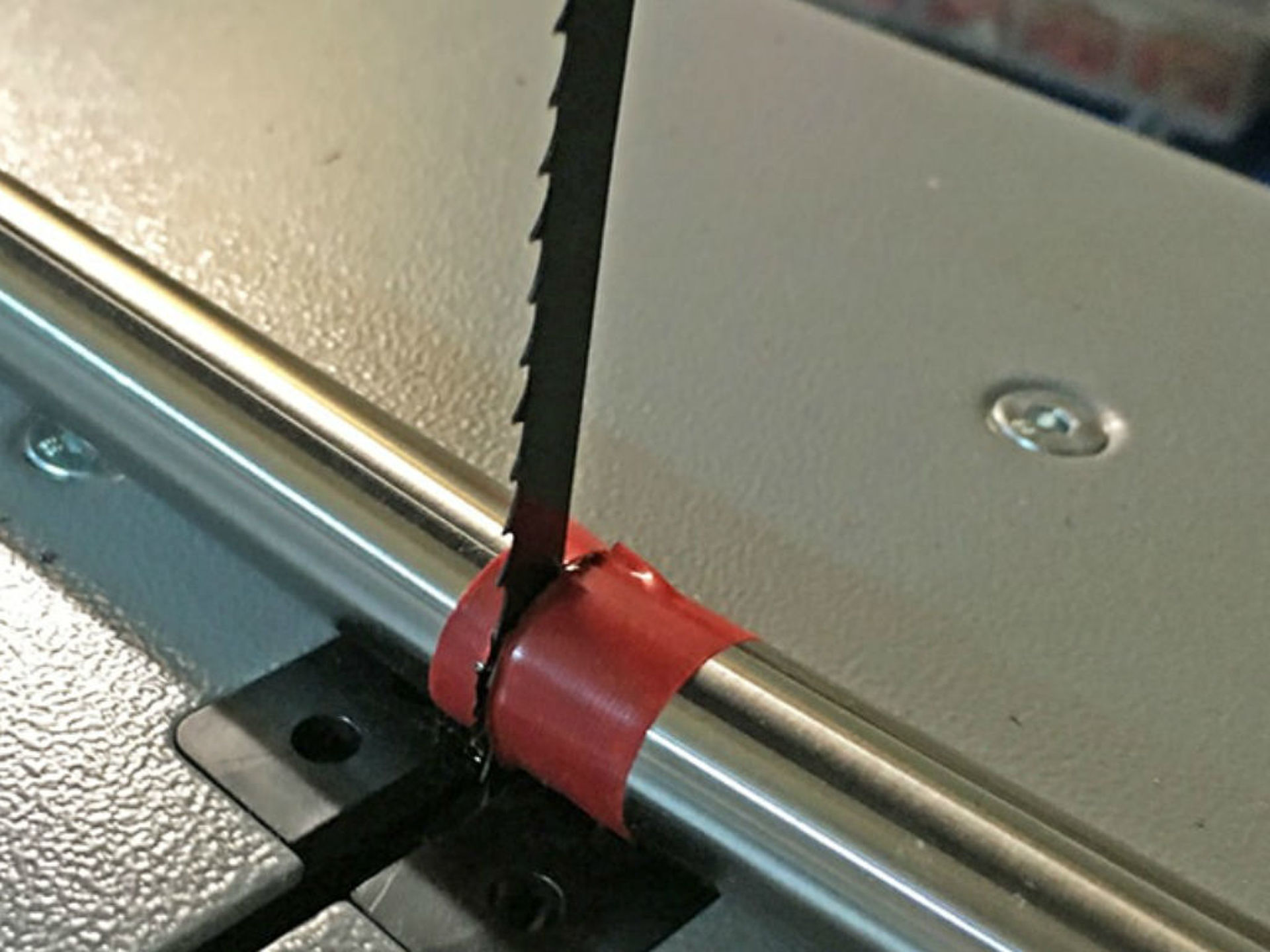

When working with the band saw it is not absolutely necessary to attach different saw blades for different materials. Whether wood, aluminium, thin iron, brass or copper, the band saw's universal saw blade works with all materials.

Of course, different saw blades with different toothings can also be attached to a band saw.

From wood to craft wood with the band saw

In German hardware stores real solid wood is rather rare. The choice of wood is generally limited to soft spruce wood in various strengths and forms. However, if you are planning to use hardwood or even fruit tree wood for a project, you usually end up at a timber merchant with much higher prices than you would expect from a hardware store.

If you only need small amounts of wood, the band saw will help you. The band saw makes it possible to produce high‐quality craft wood from a simple piece of wood.

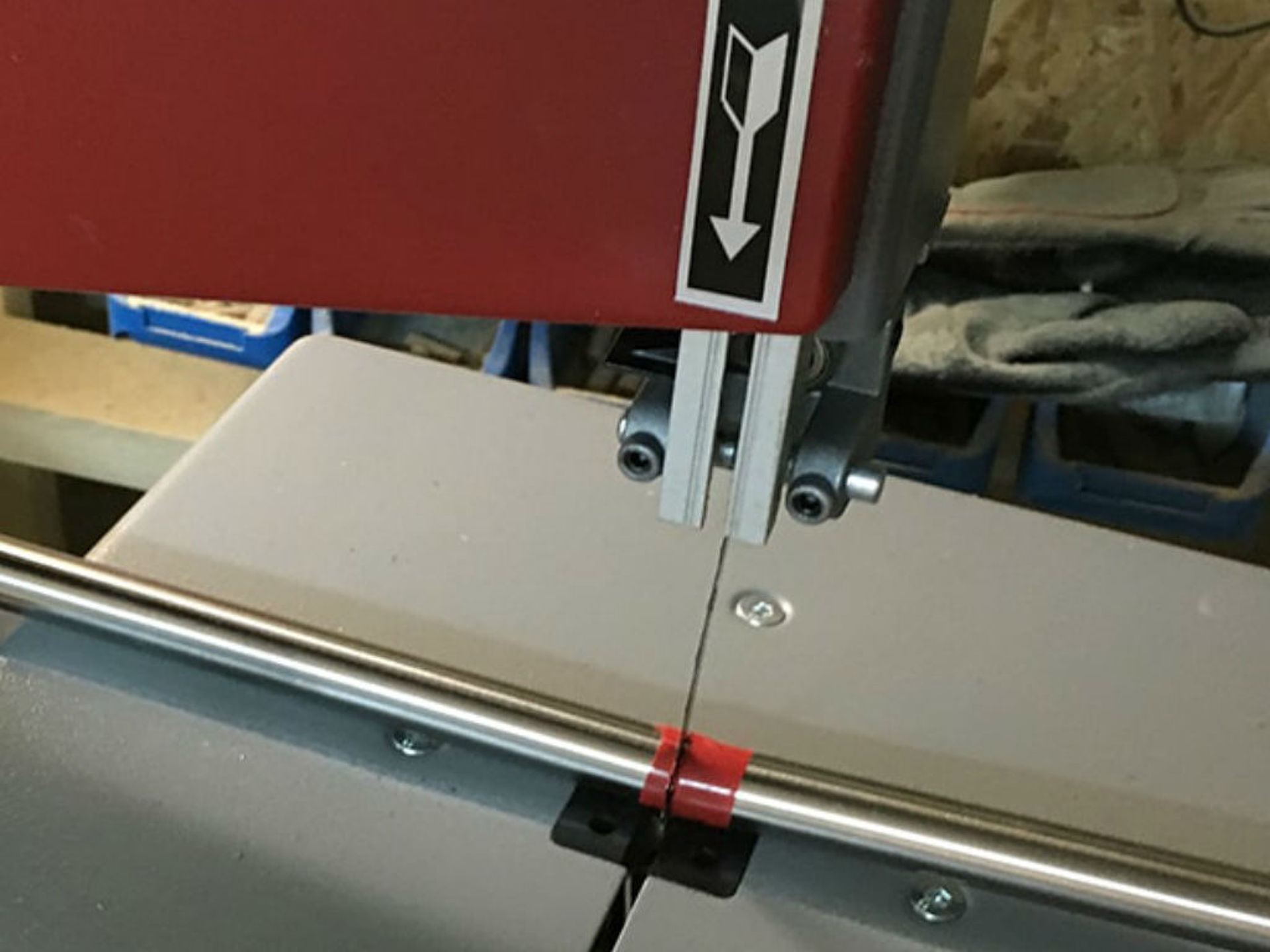

To do this, you saw the wood with the band saw in correspondingly thick strips. The rip fence of the saw ensures that all wooden strips have exactly the same form.

After the sawn strips are dry, you can straighten them with a planer and a grinder and use them for your project. Whether as a raw material or glued as a wooden board, a project made of solid wood always looks high quality!

As the saw blade, in contrast to the circular saw, is very thin, it is possible to saw very thin wood strips with the band saw. You can, for example, use this as a veneer or use wood glue to glue it into radii with several layers.

As the saw blade of the band saw is continuous and is guided on rollers at the top and bottom, the saw cut is always exactly 90°. If you want to make cuts at other angles you can adjust the saw table between the range of -4 to 46°. As a result, all conceivable angles are possible by clever turning of the workpiece.

Sawing forms

When sawing forms, the jig saw is usually used, which - as already mentioned - is available in almost every household. DIYers reflexively pick up the jig saw here. Anyone who has worked with a jig saw more often knows the disadvantages in addition to the many advantages of this type of saw. When sawing with the jig saw, the saw is guided with one hand, so there is only one hand free to hold the workpiece. Once you have done this with a band saw, you will learn to appreciate the use of the second hand when guiding the workpiece, curvy cuts are almost perfect with the band saw after a little practice. Tears in the wood fibre that typically occur on the underside when cutting with a jig saw do not occur on band saw cuts.

The band saw for furniture making

When making furniture dowels, joiners and screws are usually used, if you would like to produce particularly stable wood joints you should really opt for dovetail and mortise joints. Although these classic joints can also be made in the traditional way with hand tools, you can save a lot of time using the band saw.